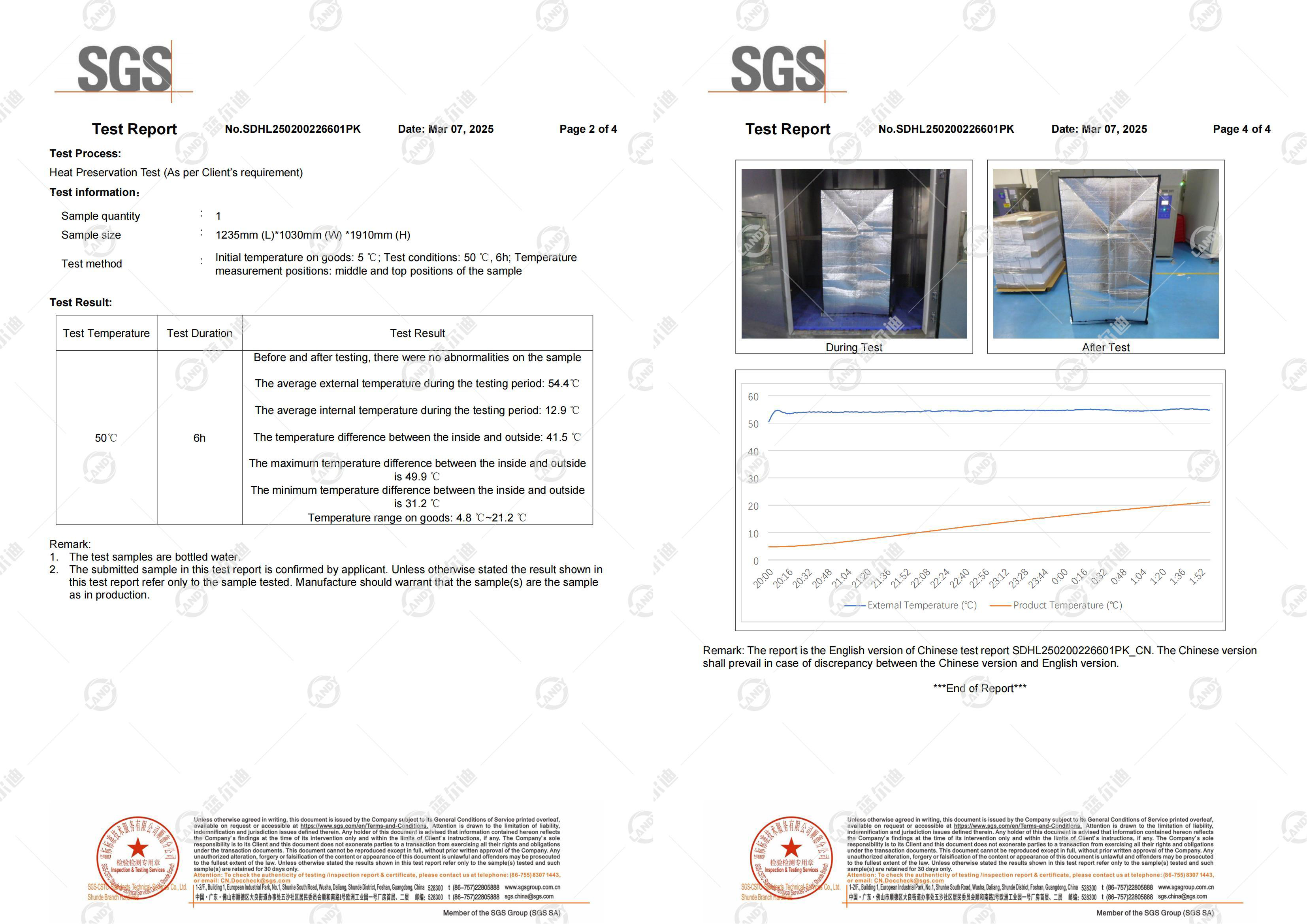

The pallet cover tested has dimensions of 1235mm in length, 1030mm in width, and 1910mm in height. Bottled water was used as the simulated cargo, which had an initial temperature of 5°C. The test was carried out in a 50°C high - temperature environment for 6 hours. During the test, the temperature changes at the middle and top positions of the cargo were closely monitored.

Average External Temperature: 54.4°C

Average Internal Temperature: 12.9°C

Average Temperature Difference between Inside and Outside: 41.5°C

Maximum Temperature Difference: 49.9°C

Minimum Temperature Difference: 31.2°C

Cargo Temperature Fluctuation Range: 4.8°C - 21.2°C

It has been detected that the average internal temperature rise rate is only 1.32°C per hour, which is superior to the industry average of approximately 2°C per hour.

Practical Applications and Certifications

These pallet covers are suitable for protecting food, beverages, pharmaceuticals, and many other temperature - sensitive goods during pallet storage and transportation. They can be customized to fit standard - sized and European - sized pallets. With SGS's testing and certification, it is guaranteed that the cargo temperature will not exceed 21.2°C within 6 hours, meeting the WHO's cold - chain drug transportation standard of ≤25°C.

Material Structure and Performance Advantages

Landy pallet covers feature a material structure composed of an aluminum foil reflective layer + a bubble buffer layer + an aluminum foil reflective layer. This structure offers triple protection: reflecting thermal radiation, insulating through an air layer, and blocking water vapor. The thermal conductivity coefficient of the material is as low as 0.036W/m·K, and its reflectivity ranges from 95% to 97%.

Thanks to its lightweight design (with a weight per unit area of 230gsm and a thickness of 3mm) and reusable nature, compared with traditional insulation boxes, it can reduce logistics costs by over 30%.

Conclusion

Landy pallet covers have passed SGS stringent tests, demonstrating outstanding high - temperature insulation performance. The thermal conductivity coefficient of its aluminum - foil bubble composite structure reaches an international advanced level. This makes it an efficient and reliable temperature - control solution for handling products in dock areas or during transportation from both sides of warehouses.

Chinese

Chinese Pусский язык

Pусский язык Français

Français Español

Español